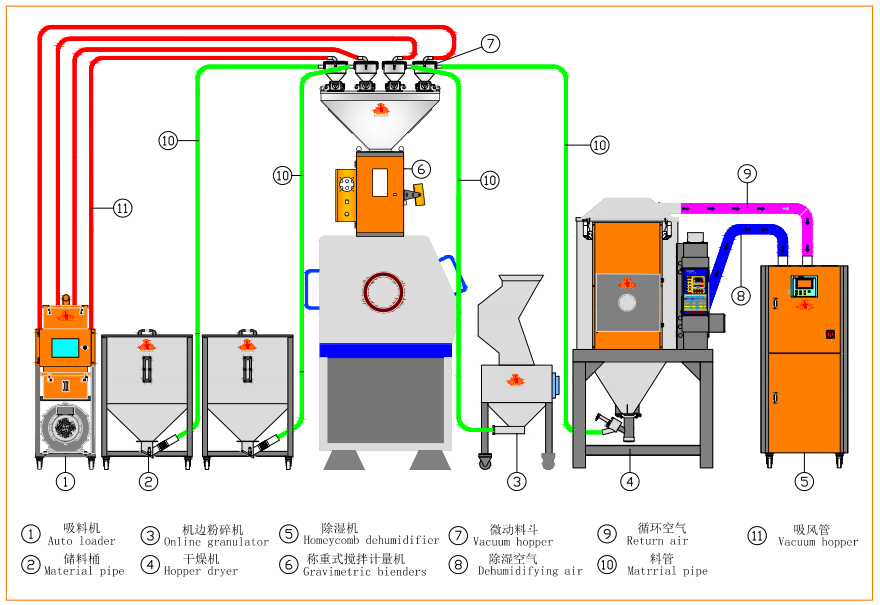

The purpose of plastic dehumidification and drying is to reduce the moisture content to the required level. The drying equipment can achieve this function by circulating the dry and hot gas in the drying hopper. When it is necessary to process many different types of materials, a central device is usually used to generate dry gas, which enters a series of hoppers through a pipeline system, and each hopper corresponds to a material.

However, due to differences in different material characteristics (such as material type and polymer consumption and particle size), in order to achieve the best operating results, each hopper requires specific working conditions. The traditional approach is to use a safe working condition, and the drying system is also set based on the most demanding process parameters, such as maximum material consumption at the highest temperature and air flow. This basic model violates the principle of energy efficiency and therefore does not help to reduce or optimize the operating costs of the system.

In order to solve this problem, a special drying system was developed, which is different from the traditional central feeding system. It automatically adjusts and controls all working parameters of each hopper, so the system only uses all the necessary energy.

This is achieved by the specific software correlating the data collected by the color sensor installed in each drying hopper barrel. It means that the patented measuring device in the air supply pipe below each hopper is used, so each The air flow in the hopper is adjusted and controlled in a timely and independent manner. In addition, this airflow is automatically adjusted by the central drying system to obtain the best process operating conditions.

【Introduction】 As the name implies, the desiccant dryer is used in a humid environment. It can also be called a dehumidifier. It sucks in humid air and delivers dry air through the operation of the dryer. . There are two kinds of desiccant dryers, both domestic and industrial. If you want to know more about the dehumidification dryer,working principle, characteristics and operation process of the desiccant dryer sent to you by the next editor.

Dehumidification dryer is a dehumidification dehumidification drying equipment! There are vacuum dehumidification dryer, three-in-one dehumidification dryer, PET special dehumidification dryer, honeycomb dehumidification dryer, runner dehumidification dryer, Tpu special dehumidification dryer and other series! It is mainly developed and designed for engineering plastics with high hygroscopicity for efficient dehumidification. The dehumidification dryer will send the dehumidified low air into one or more standard drying hoppers to improve drying efficiency and shorten drying. time. How to strictly control the moisture in the raw materials is the key to processing high-quality plastic products. We all know that many engineering plastics are hygroscopic. When this plastic is taken out from the moisture-proof seal and exposed to the atmosphere, it starts to absorb moisture in the atmosphere. If you use a general traditional hot air barrel dryer, Use outside air with moisture to dry the plastic, so this method cannot prevent the plastic from continuing to absorb moisture.

Now with the widespread use of industrial plastics, dehumidification dryers have replaced traditional hot air dryers.

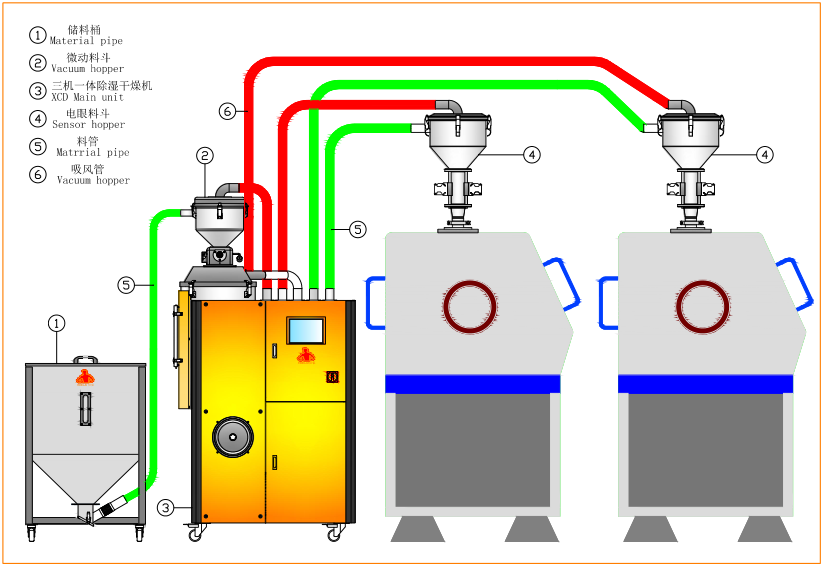

The three-in-one honeycomb rotary desiccant dryer is a new product developed based on the actual situation of the plastic industry.

The machine adopts multi-section honeycomb runner and all stainless steel double-layer down-blowing insulation hopper, integrating dehumidification, drying and feeding machines, and has the advantages of fast and simple feeding, compact structure, sturdiness and durability.

Working principle of dehumidification dryer

The dehumidifier dryer has two cycles:

1. Circulation in the dryer:

Through the operation of the compressor → discharge high temperature and high pressure gas → enter the condenser for cooling

→ Becomes a low-temperature and high-pressure gas → Cut through a capillary tube → Becomes a low-temperature and low-pressure liquid → Evaporate heat through an evaporator → Return

By then, the compressor becomes a low-temperature and low-pressure gas. This cycle back and forth.

2 .Second, the external circulation of the dehumidifier:

Under normal starting conditions → Fan operation → Inhale humid air from the air inlet →

Through the evaporator → the evaporator absorbs the moisture in the air on the aluminum plate → becomes dry air → dissipates heat through the condenser →

Blow out from the air outlet.

Dehumidification dryer application

| three-in-one dehumidification dryer |

Crystal dehumidification dryer |

Honeycomb runner dehumidification dryer |

Tpu、PET special dehumidification dryer |

There are vacuum dehumidification dryer |

|

|

|

|

0 0 |

Since most engineering plastics are hygroscopic, coupled with the influence of weather and regional climate, it is easy to cause the plastic granules to be excessively humid, and the molding effect cannot be achieved. In addition, plastic raw materials are different in the previous granulation process, so the gas moisture content and hygroscopicity are also different. Therefore, bubbles, silver bars, poor transparency, cracks, poor stability and other problems are easily generated during molding, which seriously affects product quality. The air line of the dehumidification dryer is a closed circulation system, which is not affected by the outside weather. The material can be dried well in both dry and wet weather, without moisture, and the quality of the product is high.

The dehumidifier dries the air in the environment to remove the moisture in the air at a low dew point, and then heats the dried air into one or more standard drying hoppers, which can improve the drying efficiency and shorten the drying time. If a traditional hot air blower is used to dry the material with outside air with moisture, it is difficult to achieve the drying effect. In addition, when the plastic is taken out from the moisture-proof and sealed packaging bag and exposed to the atmosphere, it will start to absorb moisture from the atmosphere. The traditional hot air fan cannot prevent the plastic from continuing to absorb moisture, and the drying effect is poor.

Therefore, dehumidification dryers are widely used in laboratories, computer rooms, measurement rooms, libraries, archives, offices, instrument rooms, hospitals, power distribution rooms, banks, material reserves, food and crop warehouses, etc., so that electronic products, Optical instruments, precision equipment and valuables avoid the bad luck of moisture and mildew.

Dehumidification dryer parameters

|

Plastic material |

Dryer |

(kg/dm3)

Density |

(h)

Drying time |

Drying temperature(℃) |

Atmospheric flow(m3/kg) |

Moulding moisture content |

Initial moisture contnt(%) |

|

ABS |

√ |

0.55 |

2-3 |

85 |

2 |

<0.020 |

< 0.2 |

|

CAB |

√ |

0.60 |

2-3 |

70 |

2 |

<0.020 |

< 0.6 |

|

EVA(2) |

√ |

0.60 |

2-3 |

90-105 |

1.8 |

- |

- |

|

EVOH |

√ |

0.60 |

2-3 |

90-105 |

2 |

- |

- |

|

LM(4) |

√ |

0.50 |

3 |

600 |

2 |

<0.080 |

<0.2 |

|

LCP |

√ |

0.80 |

3-4 |

150 |

2.2 |

< 0.01 |

<0.05 |

|

PA11 |

√ |

0.60 |

3-5 |

70-80 |

2 |

- |

0.6-1.2* |

|

PA6.46.6 |

√ |

0.60 |

4-6 |

70-80 |

2 |

0.15-0.02* |

0.6-1.2* |

|

PAI |

√ |

0.85 |

6-8 |

180 |

2 |

<0.02 |

- |

|

PAR |

√ |

0.70 |

5-6 |

120 |

2 |

<0.02 |

- |

|

PBT |

√ |

0.80 |

3-4 |

130-140 |

2.2 |

<0.02 |

< 0.15 |

|

PC |

√ |

0.65 |

2-3 |

120 |

2 |

< 0.02 |

< 0.3 |

|

PC/ABS |

√ |

0.65 |

42798 |

100 |

2 |

< 0.020 |

<0.1 |

|

PC/PBT |

√ |

0.75 |

3-4 |

110 |

2.2 |

- |

- |

|

PE.HDEPE.LDPE black3% |

√ |

0.50 |

1 |

85 |

1.6 |

<0.01 |

<0.02 |

|

PE.HDEPE.LDPE black40% |

√ |

0.70 |

2-3 |

80-90 |

2 |

<0.02 |

<0.2 |

|

PEEK |

√ |

0.80 |

3-4 |

150-160 |

2.2 |

<0.05 |

<00.1 |

|

PE(1)(3) |

√ |

0.75 |

4-5 |

140-160 |

2.5 |

<0.01 |

<0.2 |

|

PEN(1)(3) |

√ |

0.86 |

5-6 |

150-170 |

3 |

<0.005 |

- |

|

PES |

√ |

0.80 |

3-4 |

150-180 |

2 |

<0.05 |

0.35 |

|

PET |

√ |

0.84 |

5-6 |

160-180 |

3 |

<0.003 |

< 0.2 |

|

PETG |

√ |

0.74 |

4-5 |

65 |

3.5 |

<0.01 |

<0.1 |

|

PI |

√ |

0.70 |

2-3 |

120 |

2.2 |

<0.02 |

- |

|

PMMA- |

√ |

0.65 |

3-4 |

80 |

3 |

< 0.02 |

<0.3 |

|

POM |

√ |

0.85 |

2-3 |

90-100 |

2 |

- |

<0.15 |

|

PP |

√ |

0.50 |

1 |

80-90 |

2 |

- |

- |

|

PPO |

√ |

0.55 |

2 |

100-110 |

2 |

<0.01 |

- |

|

PPS |

√ |

0.80 |

2-3 |

130-140 |

2 |

<0.01 |

<0.03 |

|

PS[GPPS.EPS.HIPS] |

√ |

0.55 |

1 |

80 |

1.7 |

<0.02 |

<0.05 |

|

PSU |

√ |

0.80 |

3-4 |

120-130 |

2 |

<0.05 |

<0.1 |

|

PIT |

√ |

0.80 |

5-6 |

130-150 |

3 |

<0.05 |

<0.2 |

|

PUR |

√ |

0.75 |

2-3 |

70-90 |

2 |

<0.02 |

- |

|

PVC |

√ |

0.85 |

1 |

70-80 |

1.4 |

<0.02 |

- |

|

SAN |

√ |

0.55 |

2-3 |

80 |

2 |

<0.02 |

<0.1 |

|

SB |

√ |

0.60 |

1-2 |

80 |

2 |

<0.02 |

- |

|

TPE |

√ |

0.65 |

2-3 |

110 |

2.2 |

<0.05 |

<0.3 |

|

TPE |

√ |

0.65 |

2-3 |

80 |

2.2 |

< 0.1 |

- |

|

TPO |

√ |

0.55 |

3 |

70-90 |

2 |

- |

- |

|

TPU |

√ |

0.75 |

2-3 |

70-100 |

2 |

< 0.02 |

- |

Main features of dehumidification dryer:

1. Honeycomb flow channel with ceramic fiber as material, good dehumidification effect;

2. Can be equipped with PLC programmable touch screen, more complete functions;

3. Ultra-low dew point temperature can be obtained. Ordinary cooling water can reach a dew point of -40 ° C. Using cooler, it can reach ultra-low dew point above -50 ℃;

4. Continuous dehumidification and regeneration work to ensure that the dew point temperature is stable and that the dew point is stable below -40 ℃;

5. No pollution, ensure plastic quality;

6. The flow channel can withstand a high temperature of 1000 ° C, prevent fire, acid and alkali resistance, water washing resistance, and the average service life is more than 10 years;

7. The regeneration temperature is 180 ℃, which can save 2/3 of the time and 30-40% of energy compared with the traditional hot air dryer;

8. A dehumidifier can be used with several independent drying hoppers.

Operation process of dehumidification dryer:

1. Make sure that the installation and adjustment have been completed;

2. Please turn on the power switch of the control box and the power switch on the dehumidifier panel;

3. When the temperature rises to the set temperature, check whether it is consistent with the lower temperature;

4. Obtain the temperature indication of the water tank at any time, and perform troubleshooting and maintenance;

5. Keep 8 o'clock full at any time in the production barrel;

6. The raw materials must be dried before reaching the specified time before they can be produced;

7. Before stopping. First close the paper feed tray, pump the raw materials below, and then turn off the paper feed system.

8. The standard temperature of the baking material is as follows: "The temperature and time of the plastic raw material baking material are the set standards".

Dehumidification dryer Precautions

Precautions for use

The dehumidifier dryer should be cleaned frequently and kept clean. The dehumidifier should be placed indoors in a position. Do not block the air inlet and outlet of the freeze dryer, and clean the air filter. When the ambient temperature is lower than 15 ℃, the water droplets attached to the surface of the evaporator will freeze and weaken the effect of the dehumidifier. If the ambient temperature exceeds 40 ° C, the pressure in the system will *** and overload the compressor. The protector should cut off the line, otherwise it will damage the compressor motor. Therefore, the temperature range of the dehumidifier is 15 ℃ ~ 40 ℃. If the humidity in the air is less than 30%, it is too dry and uncomfortable, so a reliable humidity controller can be controlled to keep it in the range of 50% to 60%. During use, doors and windows should be closed as much as possible to achieve the effect of indoor dehumidification. The main body of the dryer should be flat and must not be tilted or lowered to avoid machine malfunction or abnormal noise. The water storage in the desiccant dryer is too full. In order to avoid overflowing and polluting the ground, when the body must be moved during operation, the power cord must be unplugged before pouring water into the water storage bucket. After the dehumidifier moves statically for four to six hours, then start the machine. Since the compressor piping in the dehumidifier contains cold coal, the cold coal must be returned to its original position after four to six hours after being moved. Clean the air filter regularly (about once every two weeks) to maintain dehumidification, dust removal efficiency and machine life. Clean the air filter and rinse it with clean water below 40 ℃; it is best to clean it with detergent. After washing the dust, rinse with water, dry in a cool place, and then put it back in the body. When cleaning the body, please wipe gently with a damp cloth; avoid direct splashing water to avoid damage to electrical insulation. There are sticky objects on the surface of the fuselage, which can be washed with soapy water. Avoid spraying solvents or peeling or discoloration of paint. Do not use thin rods or iron wires to dig into the machine to avoid malfunction or; in the event of power failure or long-term unused, please unplug the power cord to maintain the life of the machine. RMD three machine integrated dehumidification dryer specifications technical parameter table:

The feeding equipment of RMD series three-in-one dehumidification dryer is installed on the movable bracket.

The dehumidification dryer is composed of three parts: honeycomb transfer dehumidification dryer, heat preservation drying barrel and vacuum cleaner.

The suction machine can transfer the raw materials from the drying barrel to the forming machine, or can transfer the raw materials from the storage barrel to the drying barrel.

The vacuum motor and safety filter dust collector delivered to the two forming machines are installed inside the machine.

According to different production needs: we can provide dust-removing optical-grade vacuum cleaners to separate and collect the powder in the raw materials.

The compact design of the device is suitable for precise injection of connectors, precision gears, mobile phone communications, digital cameras and product size requirements.

Production of engineering plastic products; the moisture content of the raw materials after dehumidification and drying is low and stable, which can meet strict technical and quality requirements.

【Concluding remarks】 About the working principle of the dehumidification dryer, the editor has explained it in detail for you, as well as its characteristics and operation process. Presumably everyone will have a deeper understanding of the dehumidification dryer after reading. Nowadays, the development of desiccant dryers in the pharmaceutical industry is very extensive. Everyone knows that drugs must avoid moisture. In addition, the editor reminds everyone that when the desiccant dryer is not in use, it should pay attention to cleaning work, keep it clean, and extend its use time limit.

Central Drying System、dehumidification dryer、dehumidification dryersystm

|